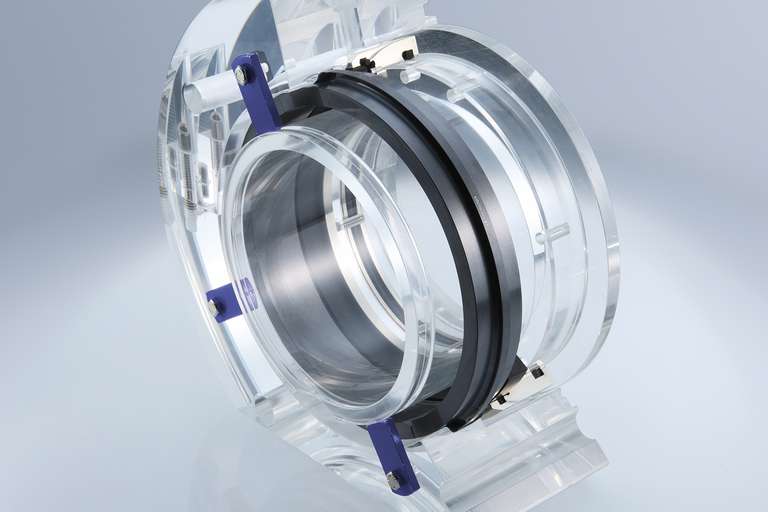

Split mechanical seals for high-performance storage pump

A seal for a shaft diameter of 550 mm (21.65") – an absolutely thrilling dimension. In close cooperation with the customer, EagleBurgmann developed the durable and robust VGH300S1/560 mechanical seal to help increase the overall efficiency of the pump in an Austrian reservoir power plant.

Read on for the entire case study...

Split seal for hydroelectric applications

EagleBurgmann provide successful and durable sealing solutions in hydroelectric applications. For example: An EagleBurgmann HGH200S1/375-E1 split seal has been in operation for more than 10 years at the Sao Joaquim hydroelectric plant in Brazil.

Operating conditions: p = 2.5 bar (36.25 PSI); t = 30 °C (68 °F).

Seals and systems for CSP

An EagleBurgmann SHV mechanical seal is installed on an Ensival feedwater pump at the Gemasolar power plant in Fuentes de Andalucía (Seville, Spain). A MAA2150 magnetic separator and a WDK5150 heat exchanger were supplied.

Operating conditions: t = max. 330 °C (626 °F), p = 117.38 bar (1,702 PSI), n = 2,970 min-1.

Stern tube seal in a turbine

EagleBurgmann provide successful and durable sealing solutions in hydroelectric applications. For example: A 4600 stern tube seal in a VA Tech Hydro CAT compact turbine ran for more than ten years at the Sylvenstein power plant in Bavaria before the first inspection took place.